Roller Covered Ceramic Rubber Sheet ceramic rubber plate,belt conveyor roller covering ceramic rubber sheet,Roller covered ceramic rubber sheet,Wear resistant ceramic rubber sheet,ceramic rubber lagging Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com

Description:

Aluminum Flat Head Solid Tin Rivet – a high-quality fastener designed for durability and reliability in various industrial applications. Ideal for use in construction, automotive, and general manufacturing sectors.

Dimension:

We offer both standard and custom sizes to meet your specific requirements. Whether you need a common size or a tailored solution, we can provide the right fit for your project.

Sample Fee:

Free samples are available for orders of less than 10 pieces. Please note that shipping costs will be covered by the customer.

Sample Time:

For standard rivets, sample delivery takes approximately 2–3 business days. For non-standard or custom designs, the sample lead time is about 5–7 business days.

Lead Time:

Standard products typically take 7–10 working days for production and delivery. For customized or special orders, the lead time is around 10–15 working days, depending on complexity and quantity.

Item Details:

Our aluminum flat head solid tin rivets are manufactured with precision and built to last. They are ideal for applications where strength and corrosion resistance are essential. With certifications such as ISO, RoHS, and CE, our products meet international quality standards. Whether you're looking for a quick sample or a full production order, we are here to support your needs with professional service and timely delivery.

Aluminum Flat Head Solid Tin Rivet

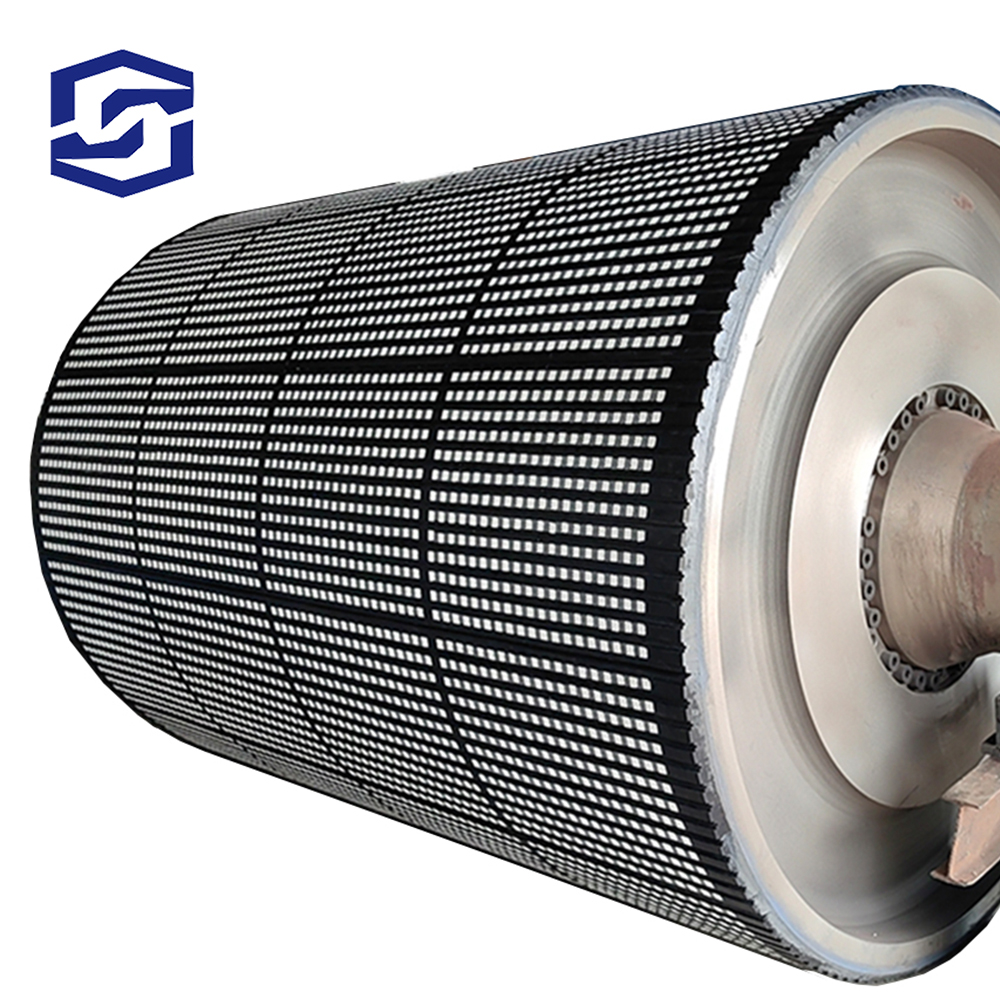

Roller covered ceramic rubber sheet is a way of cold vulcanization of roller covering, the surface of the ceramic piece can play a non-slip role, to extend the service life of the conveyor belt roller, each piece of ceramic piece is spaced at a certain distance, which can make the roller on the discharge of foreign matter,gives the drum a unique self-cleaning feature that is especially suited to wet working environments.

The combination of ceramic and rubber sheet increases the wear resistance of rubber sheet,making our ceramic rubber sheets more durable and longer lasting than ordinary rubber sheets.

The CN layer on the back side acts as a super Adhesive, the ceramic rubber sheet is more effective when used with our Adhesive!

Due to the multiple performance advantages of ceramic rubber sheets, they are now widely used in belt conveyor rollers in coal mines, grain silos, iron and steel, chemical fertilisers, cement factories, power plants, harbours, wharves and many other industries.

If your belt conveyor roller equipment is not durable, come and have a look our ceramic rubber plate, you will have an efficient, stable and environmentally friendly conveying solution. Our ceramic rubber sheet is not only a product, but also a powerful assistant for you to improve the competitiveness of your enterprise and achieve industrial upgrading.

Come and contact us to start your excellent conveying journey and make the future production road smooth and unobstructed!