valve, valve for refrigeration, control valves,ball valve,Self Tapping Saddle Valve SUZHOU YOUDE ELECTRIC CO., LTD. , https://www.unitekool.com

Spring Time for Preventive Maintenance

Spring cleaning isn’t just for your home—it’s essential for your solar system too! After enduring the harsh conditions of winter, including snow, ice, and rain, solar panels and their components can suffer from wear and tear. Regular inspection and maintenance not only restore efficiency but also help avoid costly issues as the warmer months approach.

**Why does this matter for owners and investors?**

The peak generation period for solar systems typically runs from April to September. Any unexpected downtime during this time can significantly impact revenue, especially for commercial or utility-scale installations. Ensuring your system is in top condition before this critical window starts is key to maximizing returns.

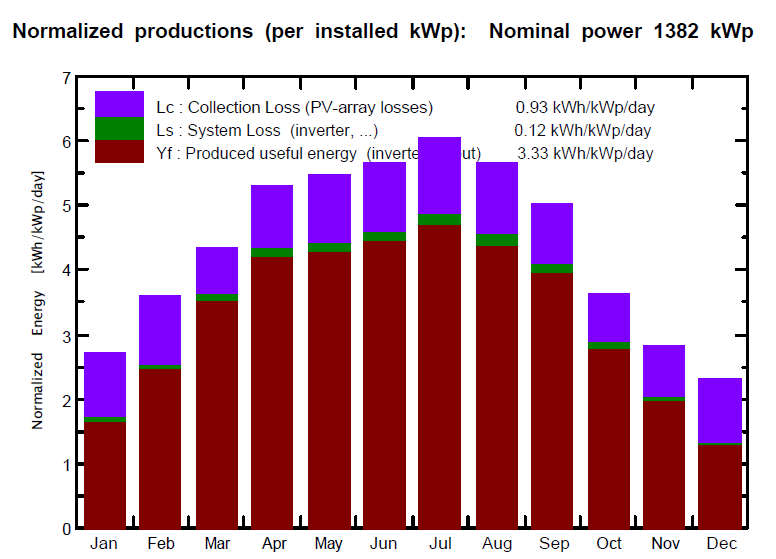

Here’s a look at typical seasonal performance for ground-mounted solar systems in the Northeastern U.S.:

**What’s included in a preventive maintenance (PM) check?**

**Step 1 – Visual Inspection and Repair**

A thorough visual assessment helps identify visible damage or potential risks. This includes checking:

- The integrity of wire management—broken wires can cause arc faults, outages, or even fires.

- Structural components for loose hardware or signs of corrosion.

- Inverter and ventilated equipment filters—cleaning them prevents overheating and improves efficiency.

- Removal of pests, nests, and debris from panels, racking, and enclosures. Sealing entry points is crucial to prevent future infestations.

- Checking that all weather instruments are clean, functional, and properly aligned.

**Step 2 – Diagnostic Inspection and Repair**

Some issues require more advanced tools to detect and resolve:

- Infra-red (IR) scans of electrical connections to detect overheating or poor continuity.

- Aerial IR scans of the entire solar array to identify hotspots or cold spots quickly.

- IV curve tracing to pinpoint the root cause of performance issues, beyond what IR scans can show.

**Step 3 – Performance Testing**

Finally, we test the system to ensure it's operating at its best:

- Confirm that the data acquisition system (DAS) is reporting accurately.

- Review annual performance metrics to identify any deviations from expected output. Tools like performance ratios or regression tests help determine if the system is meeting its design goals.

**What should you do before the PM?**

It’s ideal to monitor your system throughout the year. Monthly performance reports can help catch small issues early, preventing them from becoming major problems. However, some repairs may be better scheduled during the PM to reduce costs by minimizing unnecessary site visits. Planning ahead ensures your system is ready for the high-demand summer months.

Next Article

Spring Time for Preventive Maintenance