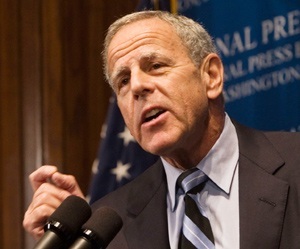

Jim Press's journey through the automotive industry reads like a tale of ambition and misfortune. Press kicked off his career with Ford in the late 1960s before transitioning to Toyota, where he spent the next 37 years climbing the ranks. His contributions to Toyota were nothing short of monumental, leading him to become the first non-Japanese individual to serve as President of Toyota Motor Sales U.S.A. In this role, he oversaw everything from parts and accessories to engineering and manufacturing across 15 plants nationwide. Under his leadership, Toyota became the second-largest automaker in the U.S., earning him respect and accolades throughout the industry. However, in September 2006, Press made a bold move by joining Chrysler as its Vice Chairman and President. At the time, he expressed excitement about being part of an iconic American brand, stating his passion for both Toyota and Chrysler. Despite his enthusiasm, his tenure at Chrysler was marred by challenges. As the company sought financial aid from the government, Press implemented cost-cutting measures, including dealership closures and layoffs, which earned him a reputation as the "bad guy." When Fiat gained control of Chrysler, Press was dispatched to Washington to justify these decisions, only to face backlash upon his return. Shortly afterward, he was let go. Beyond professional setbacks, Press faced personal financial issues. He reportedly owed over $1.4 million in unpaid taxes and defaulted on a loan from Toyota's credit union after it merged with another. This marked an unexpected downturn for someone who had once been at the pinnacle of corporate success. Reflecting on his choices, one can't help but wonder how things might have unfolded differently had he remained loyal to Toyota. For those interested in similar topics, here are some related posts:

Plastic gaskets are commonly used as an alternative to metal and demonstrate good durability and corrosion resistance. Gaskets of this type are typically lightweight and low friction with good sealing and insulation properties.

Hony plastic specializes in precision plastic gaskets and seals for applications and industries worldwide. We provide custom plastic components including plastic gaskets, plastic seals.

We typically die cut plastics ranging from .001″ to .125″ thick; however we are also capability of cutting most plastics up to 1″ thick when utilizing our water jet and laser cutting processes. We can custom manufacture quantities from prototype and short run through large production runs. Custom Gasket`s technically-oriented professionals have extensive knowledge of plastic materials and work closely with customers to create custom plastic components to meet their exact specifications. Custom Gasket Mfg. takes pride in its ability to consistently provide custom plastic products guaranteed to meet your specifications and function perfectly within your application.

Hony plastic maintains a full line of plastic materials. Plastics are available in a broad range of thicknesses, hardness and colors. They are available with or without pressure sensitive adhesive (PSA) backing. The most common materials used include:

Plastic gasket compared with metal gaskets, it has excellent insulation, corrosion resistance, heat insulation and non-magnetic properties, and is light in weight. It is widely used in various fields such as semiconductor, automobile, aerospace industry and interior decoration. There are more than 10 kinds of materials used, including PA66, PC, special engineering plastic PEEK with the best performance, RENY reinforced with glass fiber, PPS, fluororesin PTFE, PFA and PVD, etc.

Ptfe Modified Seal,Peek Washer Seal,vespel gasket,torlon gaskets,gaskets,seals,PAI gasket,torlon gaskets,gaskets,seals Hony Engineering Plastics Limited , https://www.honyplastic.com

Torlon® PAI Gaskets

Jim Press: The Rise and Fall

Next Article

Car fire in Harvey

Prev Article

Toyota Used Car Buying Tips – Private Seller

Parts Suppliers Cry For Help

Parts Suppliers Cry For Help

Parts Suppliers Running For Cover

Parts Suppliers Running For Cover

Cash for Clunkers: Just Another Headache…

Cash for Clunkers: Just Another Headache…

CEO Switch

CEO Switch

Toyota Owners Online

Toyota Owners Online

New Scion Products

New Scion Products