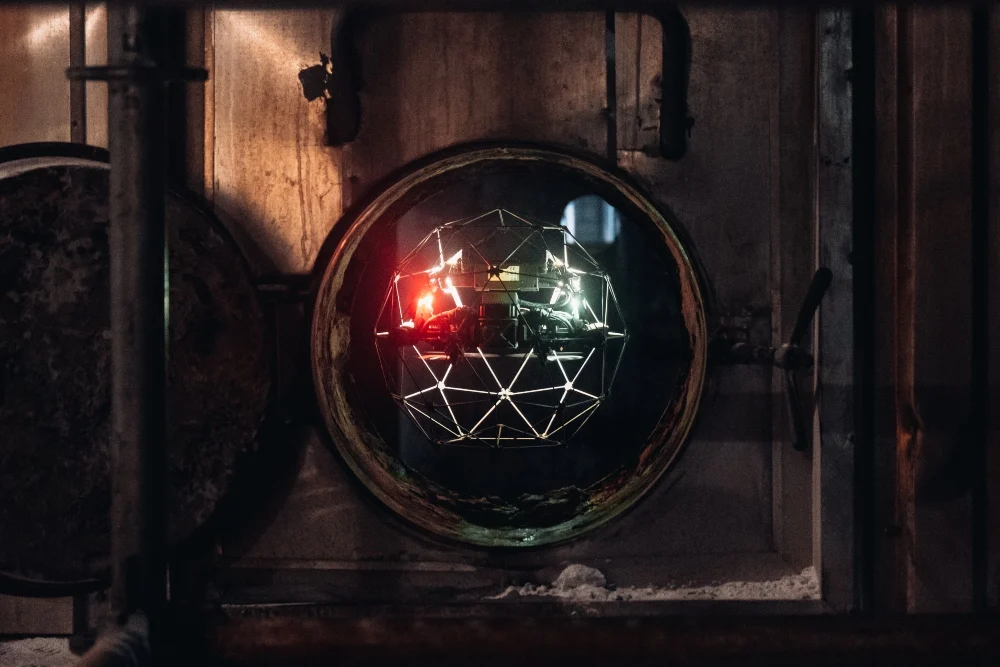

Inspectors in the field of Non-Destructive Testing (NDT) today rely on a variety of tools to gather data remotely. These tools are commonly known as RVI, or Remote Visual Inspection, which refers to the ability to collect information from a distance. This method has become essential in many industries where direct access to equipment is either dangerous or impractical. The main goal of RVI is to capture visual data—such as images and videos—that show the condition of critical parts of an asset. This helps identify potential defects that may need further examination or maintenance. An RVI tool can range from something as simple as a camera suspended by a rope to advanced systems like Flyability’s Elios 2 drone, which is designed specifically for internal inspections. These devices allow inspectors to collect high-quality data without entering hazardous environments. Whether it's a boiler, pressure vessel, chimney, or another structure requiring entry, using RVI ensures that inspectors can safely gather necessary information without putting themselves at risk. Indoor drones have become one of the most valuable tools in this process, offering multiple advantages for NDT professionals. Keep reading to discover the top seven benefits of using indoor drones for NDT in indoor inspections. Non-Destructive Testing (NDT) involves a set of inspection techniques that allow engineers and inspectors to evaluate the integrity of materials and structures without causing any damage. Visual data is the most commonly used form of NDT, but other methods such as ultrasonic testing or radiography are also frequently applied depending on the situation. Indoor inspections often involve confined spaces that pose significant risks to human workers. The primary dangers include falling, being trapped, and exposure to harmful gases. In some cases, like grain bin inspections, the material itself can be a hazard. Using drones eliminates these risks entirely, allowing inspectors to collect high-quality visual data from a safe distance. Drones like the Elios 2 are designed to operate in tight, hazardous environments, making them ideal for internal inspections. By replacing manual entry with remote data collection, drones significantly reduce the risk of injury or even death during inspections. [Related reading: What Is the Hierarchy of Control?] Using drones for visual NDT instead of sending personnel into confined spaces can lead to substantial cost savings. Here are the main financial benefits: Real-world examples demonstrate the impact of these savings. One company saved $2 million using the Elios 2 for oil tanker inspections, while another saved over $420,000 with the Elios 1 before upgrading to the Elios 2. Because drones are more cost-effective than traditional methods, companies can conduct more frequent inspections. This leads to earlier detection of defects, allowing for timely repairs and extending the life of assets. In addition, increased inspection frequency can support sustainability goals. A study found that using drones for boiler inspections could reduce CO2 emissions by up to 649 metric tons annually, highlighting the environmental benefits of drone technology. When it comes to maintenance, knowing exactly where a defect is located is crucial. Flyability’s Inspector 3.0 software allows inspectors to map out defects with precision, providing a point cloud that shows the exact location of each issue identified during an inspection. This level of accuracy improves communication between teams and streamlines the repair process. It also helps ensure that maintenance efforts are targeted and efficient, reducing unnecessary work and costs. Unlike manual inspections, which may only capture limited visual data, drone flights record the entire inspection process. This creates a detailed historical record of an asset’s condition at a specific point in time. With the right software, this data can be transformed into 3D models or point clouds, giving engineers a comprehensive view of the asset’s state. This is especially useful for tracking the progression of defects or analyzing the cause of incidents. In many cases, human inspectors cannot reach certain areas of an asset due to physical or legal constraints. Drones, however, can navigate tight spaces and provide access where humans cannot. For example, in sewer inspections, drones can enter pipes filled with dangerous gases or fast-moving water. In wind turbine inspections, they can reach blade sections that are otherwise inaccessible. Similarly, in bridge inspections, drones can examine hard-to-reach areas like between beams or inside box girders. Indoor drones like the Elios 2 are built with protective cages, allowing them to safely operate in confined and complex environments. This makes them ideal for capturing data in places that would otherwise be impossible to inspect manually. Modern drone technology enables inspectors to capture high-resolution video and still images, creating a detailed visual record of an asset. This data can be reviewed later, helping to monitor changes over time and detect early signs of wear or damage. Advanced software tools can also extract precise measurements from the captured data, improving the accuracy of inspections and supporting more informed decision-making. Overall, drones provide a reliable and consistent way to collect and analyze visual data, making them an essential part of modern NDT practices. Polycarboxylate Ether Powder 99% (Super Plasticizer) show Extremely High Water Reduction in Concrete with Improved Work Ability and Increase in Strength by Almost 20-30% Depending on Use. These show good work ability in Concrete at even at water cement ratios as low as 0.23. PCE Powder,Water Reducing Type PCE,PCE Powder Polycarboxylate Ether,Raw Material Pce Powder Liaoning Kelong Fine Chemical Co.Ltd. , https://www.kelongchemy.com

What Is NDT?

The 7 Major Benefits of Indoor Drones for NDT in Indoor Inspections

1. Improved Safety

2. ROI & Savings

3. Increased Frequency of Inspections

4. Data Localization

5. Providing a Historical Record

6. Improved Access within Assets

7. Higher Quality Data

Polycarboxylate Ether Powder is the Third Generation of Excellent Quality Superplasticizers Show Extremely High Water Reduction in Concrete with Improved Work Ability and Increase in Strength by Almost 20-30% Depending on Use.

The 7 Major Benefits of Indoor Drones for NDT in Internal Inspections

Next Article

Toyota Brake Caliper Buyer's Guide