, fuel dispensing pump, petrol dispenser, diesel fuel dispenser, gasoline dispenser Henan Wenjia Energy Technology Co., Ltd , https://www.hnwjny.com

Overview of Bearing and Seal Types

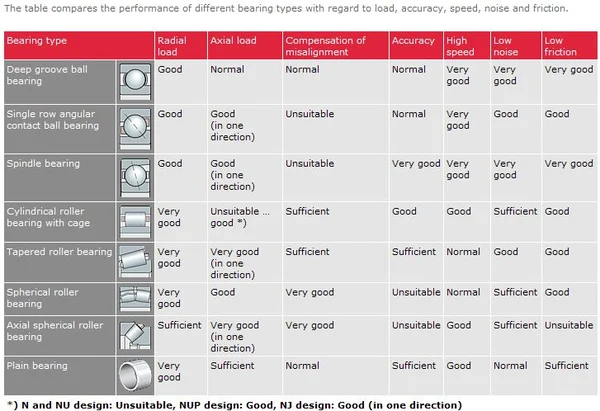

For any application involving equipment with rotating or moving parts, choosing the right bearing and seal is crucial. Bearings play a key role in enabling smooth rotation and linear motion while reducing friction and evenly distributing the stresses caused by radial and axial loads, which could otherwise lead to catastrophic failures. Meanwhile, seals ensure that the necessary lubricants remain inside the bearing while keeping out contaminants or harmful particles.

If you're looking for a bearing and/or seal solution but aren't familiar with the technical terms and descriptions of the various types available in the market, this guide will serve as an introduction. It will also explain the applications of each type of bearing and seal.

### Anti-Friction Bearing Types

The two main categories of anti-friction bearings are ball and roller bearings. Roller-type bearings typically consist of two rings with a set of rolling elements moving along their tracks. Ball bearings, on the other hand, are spherical and spin rapidly, but they are best suited for moderately to heavily loaded applications such as small servo motors to large pumps and compressors. Their shaft diameters can range from 2mm to 150mm.

There are several types of roller bearings:

- **Cylindrical rollers** make deeper contact with the outer rings and distribute the load over a broader surface.

- **Needle rollers** resemble cylindrical rollers but are longer and thinner.

- **Tapered rollers** are narrower at the ends but have a unique overall shape.

- **Symmetrical barrel rollers** are self-aligning and identical on all sides, whereas **unsymmetrical barrel rollers** are also self-aligning but vary in shape.

### Sealing Types

Seals are critical for protecting and ensuring the proper functioning of your chosen bearings. The selection of sealing configurations should align with the specific application requirements.

- **Non-rubbing seals** produce minimal friction beyond the lubrication used during operation.

- **Rubbing seals** require a certain level of contact pressure to function correctly.

- **Gap seals** are designed to reduce the gap between the shaft and housing units.

- For applications needing a robust sealing effect, **labyrinth seals** are recommended as they provide better space closure compared to gap seals.

---

### Bearings and Seals from Emerson Bearing

Emerson Bearing has been a leading provider of ball and roller bearings for over five decades. To learn more about how each type of bearing and seal operates and the roles they fulfill, visit the Bearings 101 section on the Emerson Bearing website.

Below is a video demonstrating the importance of selecting the right bearing and seal solutions for industrial machinery:

Next Article

Interview with a Longtime Fan

Prev Article

Overview of Bearing and Seal Types