Four Hoses Double Products Fuel Dispenser,Double Hoses Double Products Fuel Dispenser,Gasoline Three Products Fuel Dispenser,Diesel Three Products Fuel Dispenser Henan Wenjia Energy Technology Co., Ltd , https://www.hnwjny.com

Overview of Bearing and Seal Types

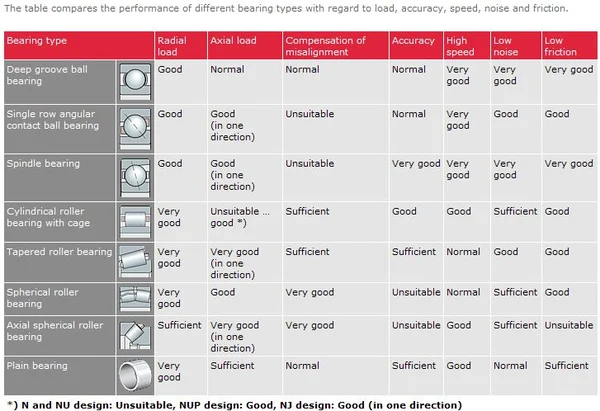

For any machinery requiring components that rotate or roll, selecting the right bearing and seal is critical. Bearings play an essential role in enabling smooth rotation and linear motion in a variety of mechanical and non-mechanical systems, while also minimizing friction and distributing the stresses of radial and axial loads to prevent catastrophic failures.

Meanwhile, seals are crucial for keeping the required lubricants inside the bearing and preventing contaminants or harmful particles from entering the gap. If you're looking for a bearing and/or seal solution but aren't familiar with the technical jargon or descriptions of the many types available, this guide will provide a comprehensive overview. It will also explain the applications of each type of bearing and seal.

## Anti-Friction Bearing Types

There are two primary categories of anti-friction bearings: ball and roller. Roller bearings typically consist of dual rings with rolling elements moving along their tracks. Ball bearings, on the other hand, are spherical and rotate quickly, making them suitable for moderate to heavy-duty applications like small servo motors and large pumps or compressors. The shaft size can range from 2mm to 150mm.

Within the roller bearing category, there are several subtypes:

- **Cylindrical Rollers**: These have deeper contact with the outer ring, spreading the load over a wider area.

- **Needle Rollers**: Similar to cylindrical rollers but longer and thinner.

- **Tapered Rollers**: Narrower at one end, with a distinct shape that helps distribute weight.

- **Barrel Rollers**: These come in symmetrical and asymmetrical forms, with the latter being self-aligning.

## Sealing Types

Seals are indispensable for protecting and maintaining the performance of your chosen bearings. The type of seal you choose should align with the specific needs of your application.

- **Non-Rubbing Seals**: These produce minimal friction, relying only on the lubrication present during operation.

- **Rubbing Seals**: Require some degree of contact pressure to function correctly.

- **Gap Seals**: Designed to reduce the gap between the shaft and housing units.

- **Labyrinth Seals**: Offer enhanced sealing capabilities for more demanding applications, providing better closure than gap seals.

## Bearings and Seals from Emerson Bearing

Emerson Bearing has been a trusted name in ball and roller bearings for over fifty years. To learn more about how each type of bearing and seal operates and the roles they fulfill, check out the Bearings 101 section on the Emerson Bearing website.

---

While selecting the right bearing and seal is important, understanding their maintenance and longevity is equally crucial. Regular inspections and timely replacements can significantly extend the lifespan of your equipment. Additionally, factors such as temperature, speed, and environmental conditions should always be considered when choosing the appropriate bearing and seal combination for your specific application. Proper selection not only enhances machine efficiency but also reduces operational costs in the long run.

If you're unsure where to begin, consulting with a professional or reaching out to Emerson Bearing's customer support team can provide tailored guidance based on your unique requirements. Remember, the right bearing and seal can make all the difference in ensuring the reliability and longevity of your machinery.

---

In summary, whether you're dealing with high-speed industrial equipment or precision instruments, understanding the nuances of bearings and seals is key to maintaining optimal performance. By choosing the correct type and ensuring proper maintenance, you'll not only safeguard your investment but also enhance the overall efficiency and lifespan of your machinery.

For further insights into bearing technology and seal solutions, consider exploring industry publications or attending seminars hosted by leading manufacturers. Continuous learning and adaptation are vital in staying ahead in today’s rapidly evolving engineering landscape.

Next Article

Overview of Bearing and Seal Types

Prev Article

The Evolution of TRUMPF Machinery